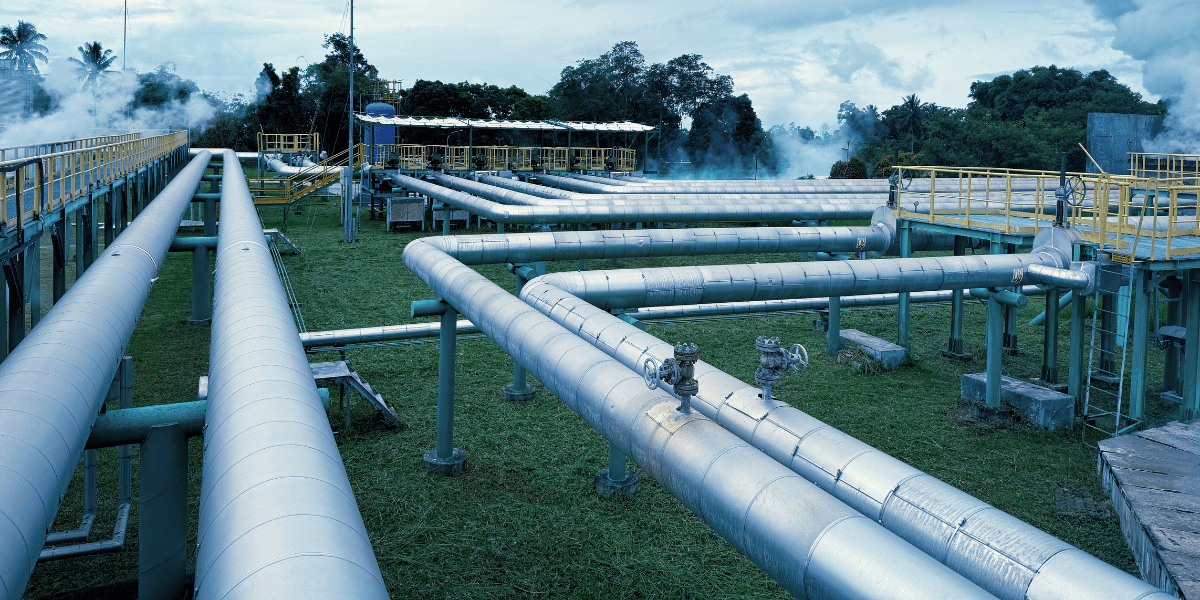

Flow assurance sounds simple until you’re the one responsible for keeping a well from slowing down because wax, scale, or restrictions decide to take over. Anyone who spends time around production knows fluids don’t behave the way textbooks promise. Pressure drops, temperature shifts, and changing water chemistry all move the target in different directions. Field conditions rarely stay still. Because you know, even the strongest well can act like it’s trying to retire early if you don’t manage what’s happening inside the tubing and flowlines.

Production chemicals are the tools that keep all those moving parts from turning into operational problems. They don’t need to be flashy; they just need to work. The goal is simple: keep hydrocarbons moving from the reservoir to sales without unplanned shutdowns, costly cleanouts, or surprises in the morning rate report.

Flow Assurance Realities from the Field

In the Permian, Eagle Ford, Bakken, DJ, and SCOOP/STACK, produced fluids bring their own chemistry set with them. Salts, gases, solids, organics, mix all that with pressure and temperature changes, and you get:

- Wax fallout when fluids cool.

- Scale precipitation when water chemistry shifts.

Core Production Chemicals Used to Keep Wells Moving

Instead of thinking of chemicals as generic additives, think of them as targeted tools chosen for the exact problem happening inside the system.

Paraffin & Wax Prevention

Paraffin deposition depends on temperature changes and crude composition. Wells with long flowlines or slow-moving fluids may see paraffin appear sooner because cooling happens faster than the fluid can carry solids. Inhibitors modify wax crystal formation; however, injection of inhibitors must be prior to paraffin formation. Dispersants keep particles suspended so they move with the fluids instead of sticking to pipe or vessels. If paraffin has already formed, solvents aid in the removal of buildup in the system.

Scale Inhibitors

CaCO₃ scale can form across pressure drops, in response to changes in pH, or in areas where temperatures increase. BaSO₄ scale can form when incompatible waters mix and does not dissolve easily once deposited. Scale inhibitors block crystal growth before it becomes a choke point. To be effective scale prevention programs apply the inhibitor prior to scale deposition in the system. This can be through continuous injection or periodic downhole squeezes depending on water chemistry and drawdown. Tracking scale tendency with ion analysis and saturation index trends helps predict formation before it affects pump intake or causes restrictions in tubing and flowlines.

Flow Assurance is Directly Connected to Production Stability

Flow assurance is more than preventing wax or scale, it’s supporting reservoir recovery and minimizing downtime throughout the entire well lifecycle. A structured chemical program supports:

- More predictable production

- Lower LOE and fewer nonproductive days

- Longer tubing, pump, and flowline life

- Fewer cleanouts and interventions

- Better separation and treatability

- Safer operations

Many operators also rely on digital monitoring, sensor data, and trending platforms to track wax and scale activity in real time. This gives earlier visibility into changes that influence flow assurance performance.

How We Diagnose Flow Assurance Problems

When production behavior shifts, we start by diagnosing the root cause, not guessing.

Paraffin Indicators

- Higher tubing pressure

- Pump load changes

- Gradual rate decline

- Flowline pressure creep

Scale Indicators

- Treaters running hotter

- Higher ESP amps

- Injection well intake loss

- Higher deltas across equipment

We confirm findings with bottle tests, thermal scans, compatibility checks, and historical trends. The goal is to validate chemistry dosage and placement with actual field behavior.

Flow Assurance Over the Life of a Well

Early Life

- Startup stabilization

- Initial paraffin and scale control

Mid-Life

- Flowline cleaning

- Water treatment optimization

Late Life

- High water cut challenges

- Midstream compliance requirements

Each phase demands a different chemical strategy. Wells don’t behave the same from year one to year seven, and the chemical program shouldn’t either.

Discover Imperative Chemical Partners’ Flow Assurance Programs

Imperative’s teams evaluate fluid chemistry, operating conditions, and production trends to match chemicals with the actual environment. Our oilfield chemical company uses field data, water analysis trends, and lab methodologies to diagnose the source of wax and scale problems and confirm that treatment is doing its job.

If paraffin keeps choking flow, if your pump cards start running wild, or if your fire tube is covered with scale, we’ve probably seen it before, and solved it. Imperative Chemical Partners supports over 85,000 wells and 45,000+ miles of midstream infrastructure. If you want a flow assurance program backed by real field experience and validated chemical design, reach out to our team.