The Problem

Chemical scavengers are the primary solution for controlling hydrogen sulfide in produced fluids. When utilized properly, scavengers react with and remove H₂S to form byproducts that can be safely carried through the process. However, in a South Texas field, one of the Eagle Ford Shale’s largest operators was experiencing H₂S scavenger-related scaling problems at a central facility that treats approximately 2,700 barrels of oil a day aggregated from a combination of newer and legacy horizontal wells.

Amine-based scavengers had been in use and had proven effective at reducing H₂S levels, however, the operator began observing solids buildup downstream in the low-pressure vapor recovery tower (VRT), vapor recovery unit (VRU) valves, and the oil storage tanks.

The Solution

Seeking a more effective treatment solution that would maintain H₂S control while eliminating solids issues, the operator elected to transition to Imperative Chemical Partners’ SVW-40565, a non-Triazine, non-amine chemical H₂S scavenger. Unlike amine-based scavengers, SVW-40565 is a neutral-pH blend that generates a water-soluble byproduct that is readily carried out of the system with any water present, making it an excellent choice for H₂S scavenging in liquid-phase applications.

By limiting pH effects, SVW-40565’s chemical composition decreases scaling tendencies–particularly for calcium carbonate–on internal equipment surfaces, mitigating downstream solids accumulation. Moreover, the SVW-40565 solution is equally effective at removing hydrogen sulfide in both liquids and gas, making it applicable to treating single- or muti-phase product streams.

The Outcomes

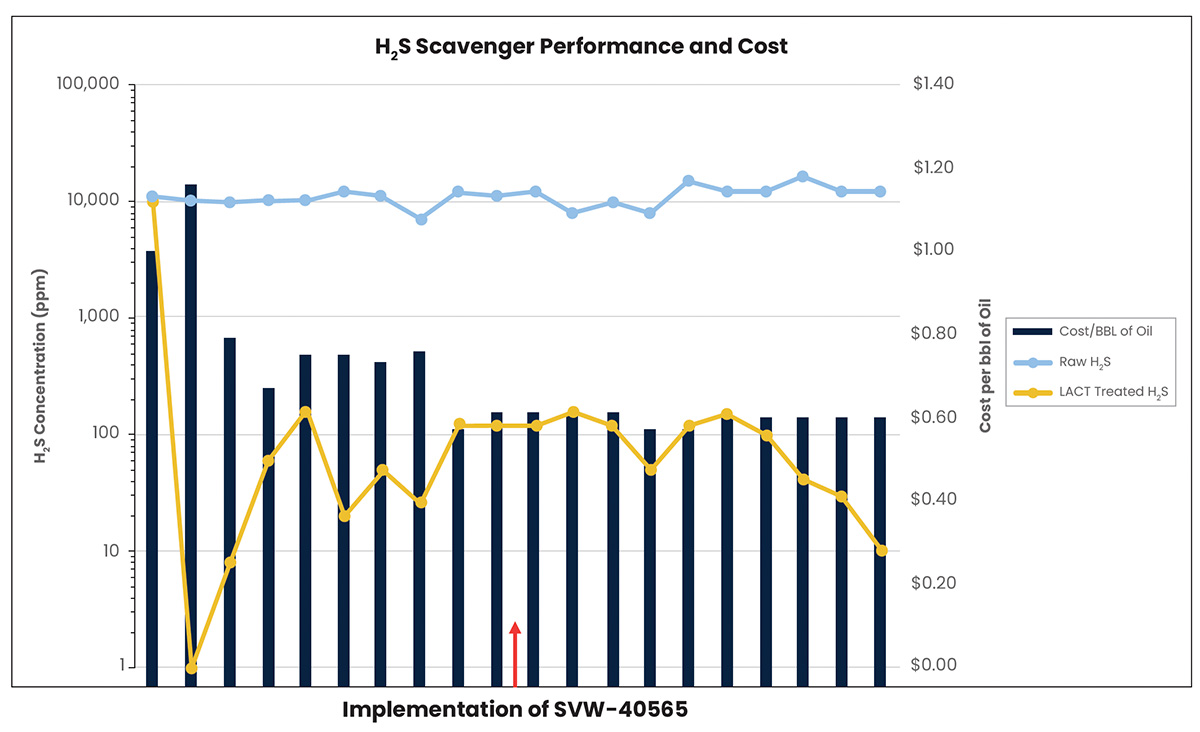

After changing over the chemical in early 2025, SVW-40565 was continuously injected with producedoil downstream of the heater treater oil dump at a comparable injection rate to the previous amine scavenger dosing rates. However, due to the lower cost of the formulation on a per-gallon basis, the operator realized an immediate 20-30% reduction in chemical spend per barrel of oil treated.

Most importantly, within 7-14 days of implementing SVW-40565 injection, solids carryover in the VRT, VRU, and oil storage tanks were eliminated while maintaining H₂S scavenging effectiveness.

The bottom-line result was optimized chemical performance at significantly less cost. The switch to SVW-40565 mitigated solids formation in the process equipment, reducing maintenance requirements, operating expenses, and downtime at the Eagle Ford Facility

SVW-40565: H2S Scavenger Treatment Cost for Eagle Ford Centralized Facility