It’s no secret that finding a new, significant oil or gas reservoir and drilling new wells is expensive. But did you know that primary recovery can leave behind more than 90% of the oil? That’s why Improved Oil Recovery (IOR) and Enhanced Oil Recovery (EOR) are so important! Keep reading to find out more about IOR vs. EOR. (Spoiler alert: EOR is actually a part of IOR.)

Defining Recovery Types

When oil producers discovered how much money they were leaving underground, new methods were developed. See below how this happened:

- Primary Recovery: In the beginning, petroleum was recovered using natural reservoir pressure. Later, artificial lift techniques like pumps were used to bring it to the surface. This stage is known as primary recovery.

- Secondary Recovery: When engineers, geologists, and scientists realized that much more oil could be produced, they looked for the most cost-effective way to increase production. Injecting water or immiscible gas proved to be the cheapest option. This marked the beginning of secondary recovery, also referred to as conventional recovery.

- Tertiary Recovery or Special Methods: This includes all techniques beyond primary and secondary recovery used to improve oil production. Initially, tertiary recovery was applied only when production began to decline. Today, however, these techniques are often planned from the beginning to maximize total recovery throughout the well’s life.

What is Improved Oil Recovery (IOR)?

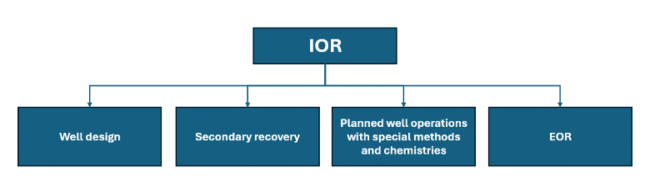

Improved Oil Recovery (IOR) includes all methods used to produce oil beyond primary recovery. This includes secondary recovery, optimized well design, and planned operations throughout the well’s lifetime. Figure 1 shows the subcategories of IOR.

Figure 1. Subcategories of IOR

Each subcategory of Improved Oil Recovery (IOR) comprises additional subdivisions, each with its own set of advantages and limitations. The process begins with a thorough reservoir evaluation and strategic decisions regarding well design—such as selecting between horizontal and vertical wells.

From the outset, Imperative Chemical Partners provides critical support by conducting initial assessments of reservoir rock, produced water, and crude oil. These insights allow for the selection and planning of the most suitable IOR techniques to optimize production from the earliest stages of the well’s life.

In some cases, IOR is not implemented during the initial development phase, leading to a natural decline in oil production over time. When this occurs, Imperative Chemical Partners can intervene by performing a comprehensive evaluation of production history, well architecture, and the reservoir’s physical and chemical characteristics. Based on this analysis, IOR strategies can be introduced to enhance oil recovery by up to 60% overtime.

IOR encompasses a range of techniques, including hydraulic fracturing, well stimulation, water injection, skin damage remediation, and completion fluid optimization. As illustrated in Figure 1, Enhanced Oil Recovery (EOR) is considered a subcategory of IOR and is widely applied across numerous oil fields globally.

What is Enhanced Oil Recovery (EOR)?

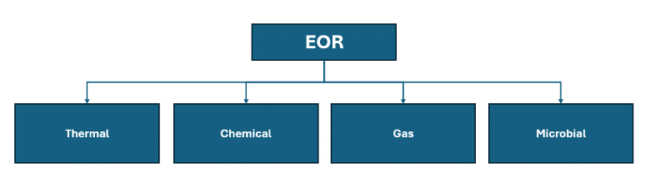

Enhanced Oil Recovery (EOR) also encompasses subcategories (Figure 2), and selecting the most appropriate method requires a comprehensive, holistic evaluation of the reservoir. One of the most commonly applied techniques is the thermal method, which increases oil temperature to improve flow. However, due to heat loss, significant recovery typically occurs only in small and thin reservoirs.

Historically, when natural reservoir pressure declined along with oil production, operators responded by drilling new wells while chemical solutions were still under development. Chemical EOR gained attention when polymers, surfactants, and alkalis began to be injected into existing wells to enhance the production of newly drilled wells.

Chemical EOR has since been widely adopted in mature fields, achieving high success rates and improving oil recovery by up to 30%. Due to its strong sweep and displacement efficiency, chemical EOR (cEOR) is now frequently incorporated into conceptual field plans, alongside other Improved Oil Recovery (IOR) methods.

Figure 2. Subcategories of EOR

How to decide between IOR vs. EOR!?

It is not simple. But don’t panic. We are here to work with you.

First, we’ll need to talk with you and get to know your well. We’ll go deep into the reservoir properties, produced water, oil characteristics, mineralogy, well design and production history. And we don’t stop there. What matters to you matters to us. Whether you need a low freezing point, high flash point, environmentally safe products- or something entirely different- we’ll develop a solution tailored specifically for your well.

How we do this is totally dependent on our analysis and your needs. We have several equipment, patented methods, in-house developed methodologies and equipment and we can design a custom methodology to better replicate and/or understand your specific field scenario.

Do you want to know more about each oil recovery solution? Keep following us!

Get in Touch with Imperative Chemical Partners Today

Imperative Chemical Partners has facilities, plants and laboratories distributed over 40 locations across the Lower 48. In every state we are ready to provide you the chemical solution that you need. EOR, IOR, Flow Assurance, well intervention, midstream products, chemicals for drilling, cementing, completion, salt-water disposal and more. Our OPTIS® products and laboratory workflow has delivered recovery gains proven in field deployments in more than tens of thousands of wells and extensive midstream applications.

Contact our team today if you are ready to have a team committed to find a customized solution for you. If you have any questions about the right choice between IOR vs. EOR, don’t hesitate and call us too and learn about our chemical solutions company.